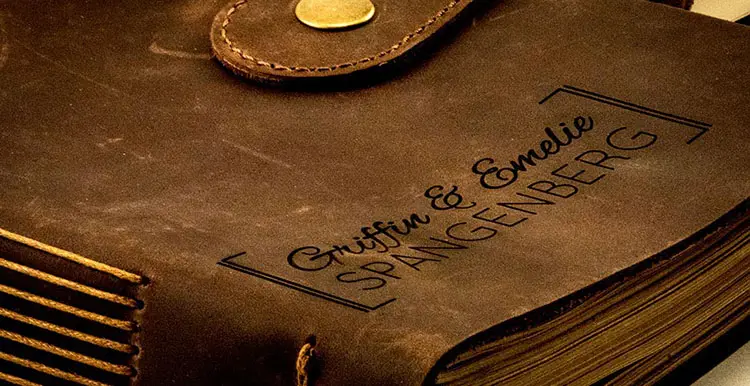

So you’ve heard about this cool thing called laser etching, right? Well, let me tell you, it’s the future of customization. Picture this: you have a plain and ordinary item, whether it’s a phone case, a piece of jewelry, or even a car part. With laser etching, you can transform that plain thing into a unique and personalized masterpiece.

How does it work, you ask? It’s all done with lasers, my friend. These powerful beams of light can precisely etch intricate designs, logos, or even text onto almost any material. The possibilities are truly endless. Whether you want to add a personal touch to a gift, promote brand awareness for your business, or simply express your own style, laser etching has got you covered. Say goodbye to generic and mass-produced items, and hello to one-of-a-kind creations that reflect your individuality.

This image is property of www.mac-laser.com.

🔥 Unbelievable Deals Await! Top Amazon Finds You Won’t Be Able to Resist! Click NOW! 🔥

Introduction

Imagine being able to personalize your belongings with intricate designs, create durable and precise markings on industrial products, or revolutionize medical procedures with precise markings on delicate instruments. Laser etching makes all of this possible. In this article, we will explore what laser etching is, its applications, advantages, techniques, suitable materials, choosing the right machine, cost considerations, challenges and limitations, and future trends in this exciting field.

What is Laser Etching?

Definition

Laser etching is a process that uses a high-powered laser beam to create precise and permanent markings on various materials. These markings are created by removing a portion of the material’s surface layer, leaving behind a permanent and visually appealing design or pattern.

Process

The laser etching process begins with a high-powered laser beam being focused on the surface of the material. The focused laser beam heats the material, causing it to vaporize or melt, which in turn creates the desired marking on the surface. By controlling the intensity, speed, and focus of the laser beam, highly detailed and precise markings can be achieved.

Equipment Needed

To perform laser etching, a few key pieces of equipment are required. These include a laser etching machine, which houses the laser beam source and controls, as well as safety measures to protect operators. Additionally, the proper ventilation system is necessary to remove any fumes produced during the process.

This image is property of cdn.carbuzz.com.

😱 You Won’t Believe These Amazon Must-Haves! Check Them Out Before They’re Gone!

Applications of Laser Etching

Laser etching has a wide range of applications across various industries. Here are three main areas where laser etching is commonly used:

Personalization of Products

Laser etching allows for the personalization of products with unique designs, patterns, or even personalized text. From customized phone cases and jewelry to personalized gifts and promotional items, laser etching provides a way to add a special touch to everyday objects.

Industrial Manufacturing

In the industrial manufacturing sector, laser etching is widely used for product identification, branding, and traceability. It allows manufacturers to create permanent, tamper-proof markings on products, ensuring authenticity and aiding in logistics and inventory management.

Medical Industry

Laser etching plays a critical role in the medical industry, where precision and durability are of utmost importance. It is used for marking surgical instruments, medical devices, and implants with unique serial numbers, logos, or other identifying information. Laser etching enables accurate and permanent markings, ensuring safety and quality control in medical procedures.

Advantages of Laser Etching

High Precision

Laser etching offers unmatched precision, allowing for the creation of intricate designs and markings with incredible detail. This level of precision is particularly valuable in applications where accuracy is crucial, such as medical instruments or electronic components.

Durability and Resilience

The markings created through laser etching are highly durable and resistant to wear, fading, or scratching. This makes laser-etched products suitable for demanding environments, where long-lasting and resilient markings are necessary.

Versatility and Flexibility

Laser etching is a versatile process that can be used on a wide range of materials, including metals, plastics, and glass. It can be applied to flat or curved surfaces, making it suitable for various shapes and forms. Additionally, laser etching allows for the creation of both shallow surface etchings and deep engravings, providing flexibility for different applications.

This image is property of cdn.carbuzz.com.

💸 Amazon’s Hidden Gems: Discover the Deals Everyone’s Talking About!

Laser Etching Techniques

Surface Etching

Surface etching is the process of creating a shallow marking on the surface of a material. It is often used for decorative purposes or to add customized designs to products. Surface etching can be utilized to create intricate patterns or logos on materials such as wood, glass, or acrylic.

Deep Etching

Deep etching involves removing a significant amount of material from the surface, creating a deeper and more pronounced marking. This technique is commonly used in applications where the marking needs to be more prominent and long-lasting, such as serial numbers on metal components or identification codes on mechanical parts.

Engraving

Engraving is a specialized form of laser etching that involves removing material to create recessed markings. This technique is commonly used to create tactile features or decorative motifs on materials such as metal or plastic. Engraving provides a visually striking three-dimensional effect that enhances the overall design.

Materials Suitable for Laser Etching

Metals

Laser etching is highly suitable for various metals, including stainless steel, aluminum, brass, and titanium. With metals, laser etching can create permanent markings or engravings that are precise and crisp, making it ideal for industrial and decorative applications alike.

Plastics

Plastics, such as acrylic, polycarbonate, and ABS, are also well-suited for laser etching. The laser beam can remove a portion of the material’s surface layer, creating precise and detailed markings. Plastics are commonly used in the production of signage, promotional items, or personalized gifts, where laser etching can add a unique touch.

Glass

Laser etching can create stunning and intricate designs on glass surfaces. Whether it’s designing custom glassware, creating decorative glass panels, or adding logos and branding to glass products, laser etching offers a precise and permanent solution.

This image is property of www.novafabrication.com.

Choosing the Right Laser Etching Machine

When selecting a laser etching machine, there are several factors to consider to ensure it meets your specific requirements:

Power and Speed

The power and speed of the laser etching machine will determine the efficiency and quality of the markings. Higher power lasers can cut through materials more quickly, while slower speeds allow for finer detail. It’s important to choose a machine that offers a balance between power and speed to achieve the desired results.

Software Compatibility

Make sure the laser etching machine you choose is compatible with the design software you plan to use. This will ensure a seamless workflow and allow you to create and import designs easily.

Work Area Size

Consider the size of the work area provided by the laser etching machine. Depending on the size of the materials you plan to work with, you may need a larger or smaller work area. Ensure the machine can accommodate your specific needs.

Cost of Laser Etching

Initial Investment

The initial cost of setting up a laser etching operation can vary depending on the size and capabilities of the machine, as well as any additional equipment or safety measures required. However, compared to traditional methods such as engraving or printing, laser etching offers a cost-effective solution in the long run.

Maintenance and Operational Costs

Routine maintenance, such as cleaning the laser lens or replacing parts, is necessary to keep the machine running smoothly. Additionally, operational costs include electricity consumption and the price of consumables like laser gas. It’s important to factor these costs into your budget.

Return on Investment

Despite the initial investment and ongoing costs, laser etching can provide a significant return on investment. The versatility, precision, and durability offered by laser etching can open up new revenue streams and differentiate your products or services in the market.

This image is property of thebossmagazine.com.

Challenges and Limitations of Laser Etching

Complex Designs

While laser etching excels in creating intricate designs, extremely complex or fine details may require additional techniques or pre-processing. These challenges can be minimized by understanding the limitations of the laser etching technology and working closely with experienced professionals.

Material Limitations

Although laser etching is suitable for a wide range of materials, there are some limitations. For example, materials with high reflectivity or transparency, such as some types of glass or certain plastics, may have reduced or altered results. It’s important to test the compatibility of materials before proceeding with large-scale projects.

Health and Safety Concerns

Laser etching machines generate highly concentrated laser beams, which can pose potential health and safety hazards if not properly operated or maintained. Adequate safety measures, such as wearing protective goggles and operating the machine in a well-ventilated area, must be followed to ensure the well-being of operators and prevention of accidents.

Future Trends in Laser Etching

3D Laser Etching

Advancements in laser technology are enabling the development of 3D laser etching techniques. With 3D laser etching, intricate and complex designs can be created on curved or irregular surfaces, opening up new possibilities for customization and product design.

Integration with AI and Augmented Reality

The integration of laser etching with artificial intelligence (AI) and augmented reality (AR) systems holds promising potential. AI algorithms can optimize the laser etching process, while AR systems can provide real-time visualizations and assistance, enhancing the efficiency and accuracy of laser etching operations.

Advancements in Laser Technology

Ongoing research and development in laser technology are continually pushing the boundaries of what can be achieved through laser etching. Advancements in laser sources, such as shorter pulse durations or higher beam quality, are expected to result in even finer details and increased efficiency in laser etching processes.

In conclusion, laser etching offers a multitude of benefits and applications across various industries. From personalization of products to industrial manufacturing and medical procedures, laser etching provides a permanent, precise, and versatile solution. As technology continues to advance, we can expect even more exciting possibilities and innovations in the field of laser etching. So, whether you’re looking to add a personal touch to your belongings or revolutionize an entire industry, laser etching is the future of customization.

🚀 Trending Now: Top Amazon Picks That Are Flying Off the Shelves!